Customer Support

SLC SUPPORT

Blog

SamSan defense coating cases | Ensuring Mission Readiness

관리자

view : 133

In the defense industry, equipment failure is not an option. The difference between success and failure often lies in the durability of the smallest components. Through various Samsan defense coating cases, we demonstrate how specialized surface treatments contribute to mission readiness and equipment survivability.

1. What Do SamSan Defense Coating Cases Represent?

SamSan Defense Coating Cases are not just a portfolio of projects; they represent a proven track record of meeting strict Military Specifications (Mil-Spec).

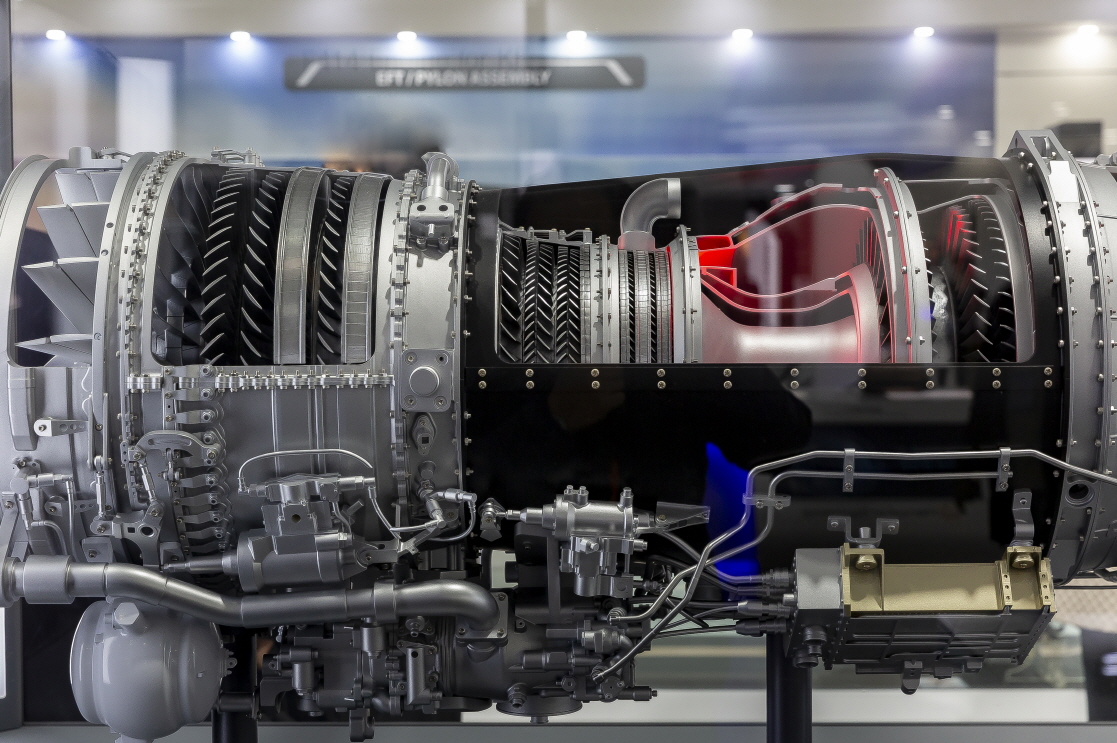

Defense equipment operates in the harshest environments on Earth—from scorching deserts to freezing altitudes and salt-laden naval conditions. These cases highlight our ability to deliver surface solutions that go beyond aesthetics to provide functional protection against extreme abrasion, chemical warfare agents, and environmental corrosion.

2. The Standard vs. The Combat-Ready (Technology Comparison)

Why can’t standard industrial coatings be used for defense applications? The answer lies in the specific data found in our SamSan Defense Coating Cases.

-

Commercial Grade: Typical coatings focus on rust prevention and color. However, they often lack the bond strength to withstand high-impact shock, recoil, or rapid thermal cycling (sudden temperature changes).

-

Samsan’s Defense Solutions: Our approach involves functional coatings designed for combat scenarios. This includes CARC (Chemical Agent Resistant Coating) capabilities and advanced lubricity formulations, such as our PFAS-free dry film lubricant, that function without oil, preventing jams caused by sand or dust accumulation—a common failure point in standard coatings.

3. Equipment and Applications (The Device)

Our expertise covers a wide range of tactical hardware. The SamSan Defense Coating Cases span several critical categories:

-

Small Arms & Weapon Systems: Coating internal moving parts (bolts, carriers) with PFAS-free dry film lubricant to ensure smooth cycling and reduced carbon buildup, allowing weapons to fire reliably even after thousands of rounds.

-

Optics and Avionics: applying non-reflective, matte-black coatings to optical housings to eliminate glare and prevent detection, while shielding sensitive electronics from electromagnetic interference (EMI).

-

Tactical Vehicles: Protecting undercarriages and heavy-duty suspension parts from extreme corrosion and rock impact in off-road terrains.

4. Strategic & Operational Benefits

The ultimate value derived from these SamSan Defense Coating Cases translates into tangible advantages in the field.

-

Enhanced Reliability: Equipment works when the trigger is pulled or the engine is started, regardless of the environment.

-

Reduced Maintenance: Adopting a PFAS-free dry film lubricant reduces the need for soldiers to constantly oil their weapons, which attracts dust. This lowers field maintenance requirements.

-

Asset Longevity: By preventing deep corrosion and wear, expensive defense assets remain in service longer, optimizing the defense budget and logistics.